Rotational molding is really a method that has been available in excess of half a century. It will allow manufacturers to generate plastic material pieces with amazing detail, utilizing much less natural resources than traditional operations. In this article, we are going to undergo rotational molding from start to finish and explore how it works.

Molds are set up through making an injections-molded version or sculpture out from clay or wax (or another gentle modeling method). The finished product is then given a metal finish to ensure that when warmed up, it can do not dissolve during manufacturing. Plastic materials are injected in to these molds at high-stress costs where by they amazing and harden almost instantly while they enter the sprue gate on their way towards turning into shaped products which are then ejected out of the fungus.

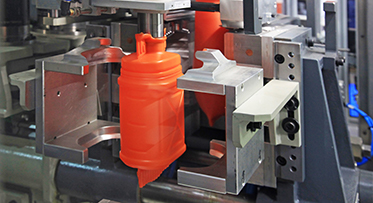

When plastics get into a rotational molding machine, these are warmed around about 270 levels Fahrenheit and injected right into a metallic-lined cylinder with cold drinking water coming from all instructions at great prices (around 100 gallons a minute).

The plastic gets into by way of a entrance referred to as the “sprue,” which is linked by hoses to a extruder go that injects or combines thermoplastic pellets for them to be easily cooled down and molded. The revolutions within these cylinders produce a vacuum outcome as molten plastic material cools down off greater than on its own because it does not have any air bubbles to cause cooling down amount of resistance. This allows for considerably faster creation days of finished merchandise.

Rotational molded components can be achieved with a wide variety of last looks. Rotational Molding is the way plastics can be done to search like metal, glass, or perhaps silicone. The depth which can be duplicated on each mold is near unlimited because of rotational molding’s ability to create incredibly complex elements all at once.

The rotational molding approach is incredibly flexible and can be used as different merchandise, such as household furniture or large parts like vehicle bumpers. It’s also productive–using about 90 moments to produce 120 parts an hour.

Rotational Molding: The Process in Detail