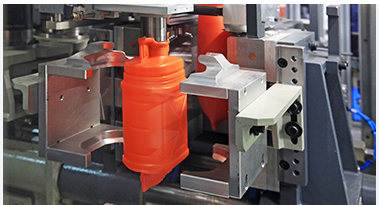

Rotational molding or Rotomolding is a preferred producing procedure for making complex plastic-type material components which can be too large to get created by traditional injection molding. One of the key advantages of Rotomolding is that it permits a wide array of materials to use, every making use of their unique properties and benefits. Within this post, we’ll consider a closer look at Rotomolding components, the many options readily available, and a few key concerns when selecting the right materials to your app.

Polyethylene (PE)

Polyethylene is probably just about the most widely used supplies in rotational molding. It’s a heavyweight, powerful, and flexible substance that is ideal for generating sizeable components that require excellent impact amount of resistance and toughness. PE also has a high potential to deal with substances and Ultra-violet rays, rendering it an excellent substance choice for exterior programs.

Nylon material

Nylon material is a superb materials selection for rotomolded parts which need substantial strength, sturdiness, and dress in amount of resistance. It’s also a excellent fabric for making elements that need reduced friction, such as gears and bearings. Nylon material could be strengthened with glass fibers to boost its power and firmness further, rendering it a great materials to get more challenging manufacturing applications.

PVC

Pvc material or Polyvinyl Chloride is actually a popular choice for rotomolded elements which require superb substance level of resistance. It’s another excellent fabric option for creating huge elements with sophisticated styles and fashions. Pvc material could be developed to become adaptable, rigid or a variety of each, so that it is a great materials for a wide array of programs for example piping, tanks, and liners.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a great fabric option for rotomolded parts that need a balance between power, toughness, and solidity. It’s a versatile fabric that could be easily shaped and is also suitable for software such as car elements, travel luggage and situations, and toys.

Go across-Linked Polyethylene (XLPE)

Cross-Linked Polyethylene or XLPE can be a great-solidity polyethylene substance which has gone through a chemical approach to improve its strength and gratifaction qualities. It’s an ideal materials for rotomolded pieces which need better stiffness and improved temperature opposition. XLPE is usually employed for developing components for example energy tanks, kayaks, as well as other underwater apps.

Things to consider in Selecting Rotomolding Components

When deciding on the best Rotomolding materials for your personal elements, several aspects should be regarded as, including product or service design and style, substance properties, and developing method needs. Several of the essential concerns include:

Component dimension and difficulty

Mechanized qualities needed – energy, flexibility, affect resistance, and so forth.

Substance resistance and UV stableness

Temperatures level of resistance

Charge

Simply speaking:

Rotomolding materials provide a wide array of alternatives according to the particular demands of your application. By choosing the proper material, you may be sure that your rotomolded parts perform optimally and stand up to the requirements of the program. Partnering by using a dependable and knowledgeable Rotomolding maker can also be vital in making sure your pieces are manufactured to the highest requirements of high quality and precision. If you’re looking to get began with Rotomolding or require assistance selecting the right material for your program, give us a call nowadays!