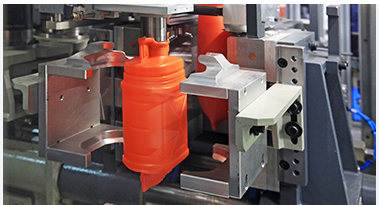

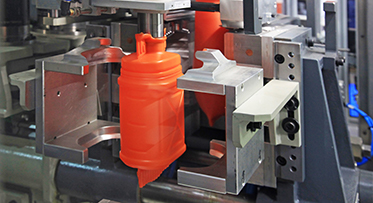

Rotational molding, as well as roto-molding, has become a dominant developing method, widely adopted for making sturdy, light and portable, and custom plastic material products. This technique, which involves heat along with revolving plastic supplies in the mildew, has got positioned themselves while a vital procedure to get companies far beyond it is very first applications. This article explores an array of substantial utilizes with Rotational Molding all around numerous groups today.

Packaging Solutions

The actual appearance industry has viewed tremendous advancement, and rotational creating plays a vital role in this particular landscape. This process generates resilient cheap bins, tanks, as well as bins which will stand up to abrasive coping with and also overwhelming climatic conditions. Rotationally shaped appearance methods may also be hugely favored with market sectors which need effortless, leak-proof hard drive choices for their products, such as chemical and also food-grade materials.

Automotive and Transportation

Among the fastest-growing makes use of with rotational creating is in the production of motor vehicle plus transportation components. Energy resource septic tanks, oxygen channels, and in some cases custom made seat answers are generally items generally created making use of this technique. Its capability to develop durable and lightweight factors can make roto-molding a hot selection throughout companies searching to enhance gasoline performance without limiting about good quality standards.

Agriculture

Growers plus garden firms trust in rotational molding regarding effective, weather-resistant products. By give food to troughs in addition to waters septic tanks for you to storage space receptacles plus tools housings, the versatility and low cost convert it into a go-to technique from the farming sector. The products are designed to withstand corrode and destruction coming from lengthy contact natural light or maybe hard substances, leading them to perfect for arduous village environments.

Healthcare and Medical

Your medical industry utilizes rotational creating to help art special apparatus plus tools. Powerful, light-weight professional medical carts, containers, and also clinic mattress pieces are made with detail applying this method. On top of that, rotational creating is utilized with designing long-lasting still light in weight ingredients pertaining to range of motion aids such as wheelchairs along with stretchers.

Recreational Products

Just what lots of individuals would possibly not know is the fact that rotational molding provides a few of their favorite fun items. Gemstone glides, kayaks, canoes, as well as patio furniture are made by using this technique. Its capability to provide easy styles makes sure your long life plus protection of they, whether or not they are for children’s engage in or perhaps voyage sports.

A Thriving Future for Rotational Molding

From strengthening structure with sectors for you to maximizing day-to-day merchandise, rotational molding’s versatility is constantly on the shape the way vital backpacks are made. Together with being able to alter to diversified needs, this particular creation technique will obviously remain the main topic on product creativity around industries.